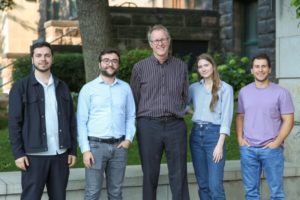

Hydrogen will play a crucial role in enabling countries worldwide to reach net-zero emission by 2050. But a sustainable hydrogen economy will require global collaboration and knowledge sharing to drive the necessary technological developments, says Professor Murray Thomson (MIE).

Thomson is the one of four national leads of the newly established Global Hydrogen Production Technologies (HyPT) Center, along with professors from Arizona State University in the United States, the University of Adelaide in Australia and Cranfield University in the United Kingdom.

The Center will advance net-zero hydrogen production technologies with the goal of making it more energy efficient and affordable by reaching US$1 per kilogram. Researchers will also explore the social and environmental system changes that are needed to build a global hydrogen economy.

“Our goal is to connect researchers and students worldwide to share insights and work synergistically to create a sustainable energy resource,” says Thomson.

“It is about connecting Canadians who work in hydrogen production and technology, but also connecting Canadians with researchers around the world, which I think is a great benefit to our students to promote new ideas, expertise and approaches.”

The Canadian component of the project will receive $3.6 million over five years from the Natural Sciences and Engineering Research Council of Canada (NSERC), providing the Center with a total of $25.5 million to support student training and mobility.

Thomson’s research is focused on methane pyrolysis, and he has co-founded a company, Aurora Hydrogen, which is creating low-cost, low-carbon hydrogen production.

“Aurora Hydrogen is growing very quickly,” he says. “We’ve hired 30 people and should have a pilot-scale plant built by the end of the year.”

He is also the methane pyrolysis leader of the new HyPT Center, which is one of three technologies the Center aims to advance. The methane pyrolysis subgroup includes researchers from Adelaide, University of British Columbia (UBC), Stanford and Cambridge.

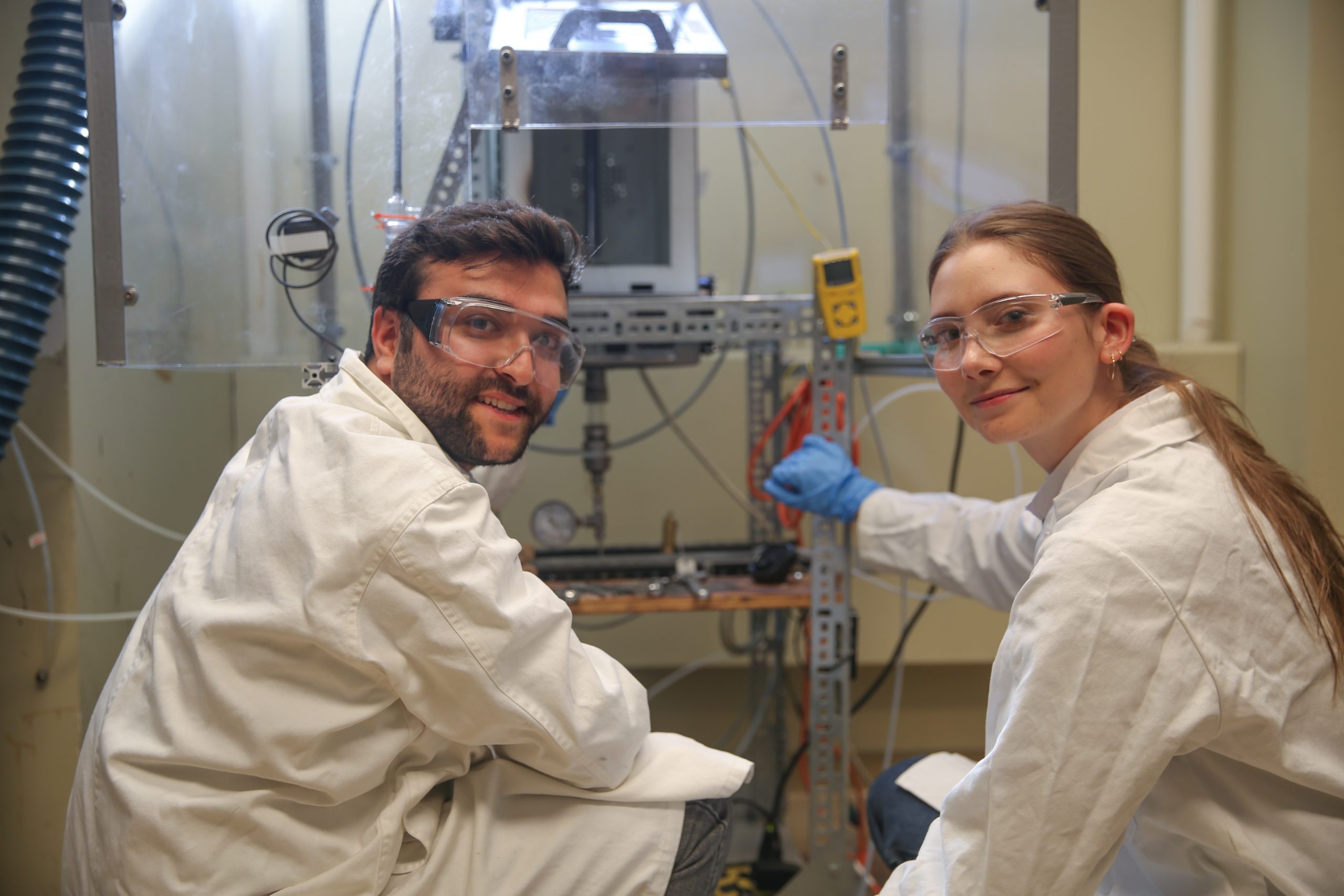

“Methane pyrolysis is a process that uses heat to break down natural gas into hydrogen gas and solid carbon particles, so that you don’t produce carbon dioxide. But that carbon is also a useful product,” says Thomson.

“My team at U of T is using microwave energy to break apart methane. Stanford and Cambridge are working more on the carbon byproduct side, while Adelaide and UBC are exploring different catalysts.

“We each have a different focus, but by interacting as a group we can work together to provide a more compelling technology.”

The other two hydrogen technologies the Center is exploring are water electrolysis, where water is split into hydrogen and water using electrical energy; and photocatalytic water splitting, which uses sunlight to separate hydrogen and oxygen.

Since both methods require lots of clean water, the Center is also exploring challenges related to this crucial resource.

“Hydrogen production is expected to increase dramatically over the next decade,” says Thomson.

“We have a role to play in better training the next generation of students working in hydrogen energy, in developing the scientific foundations that these hydrogen production technologies are based on, and in ensuring our approaches consume less electricity, use better catalysts and make more efficient use of the carbon and oxygen byproducts.

“The goal is to provide the energy that the world needs with much less greenhouse gas emissions — that is the motivation.”

– This story was originally published on the University of Toronto’s Faculty of Applied Science and Engineering News Site on September 26, 2023 by Safa Jinje.