Machine Shop - Professional Services

MIE's Machine Shop houses state-of-the-art equipment and provides technical services for:

- Faculty of Applied Science & Engineering students and faculty

- University of Toronto faculty and researchers

- University Health Network affiliated hospitals

Machine shop staff do not take on contract work for corporations, private individuals, alumni or small businesses.

How to Request Professional Services

Professional Equipment

CTX 310 Glidemeister CNC Lathe

- 14.5″ swing by 17.5″ between centres

- 6,000 rpm spindle

- 12 position tool turret

Kitamura Mycenter 3020G

- 30″ x-axis travel by 20″ y-axis travel by 20″ z-axis travel

- 20,000 rpm spindle

- 30 tool Automatic Tool Changer

- 1 micron repeatability

HAAS VF-2 SS Vertical Machining Centre

- 30″ x axis travel

- 16″ y axis travel

- 20″ z axis travel

- 12,000rpm

- 24+1 tool changer

Sodick AD325L CNC Wire EDM

- 12.5″ x-axis travel by 9.5″ y-axis travel by 8.5″ z-axis travel

- wire size of 0.006″ to 0.012″

- 15 degree per side taper cutting

- 0.1um resolution

Agie Charmilles Drill 11 NC EDM Hole Driller

- 12″ x-axis travel by 8″ y-axis travel by 12″ z-axis travel

- drill sizes from 0.006″(0.15mm) to 0.125″(3mm)

- can drill up to depth of 200 x (electrode diameter)

Sodick AD25L Sinker EDM

- Work Tank Size: 23.62" x 17.87" x 10.24"

- X-Axis Travel: 11.81"

- Y-Axis Travel: 7.87"

- Z-Axis Travel: 5.91"

- Max Workpiece Weight: 220 lbs

- Max Electrode Weight: 44. lbs

Fortus 450MC 3D Printer

Haas TM-1 CNC Tool Room Mill

- 30″ x axis travel

- 12″ y axis travel

- 16″ z axis travel

- 4,000 rpm

Roland 3D scanner

- 10″ dia x 16″ H – Work Envelope

- 0.004″ scan resolution

- rotational and planer scanning

Flow Mach 2 CNC Waterjet

- 52″ x 52″ Work Envelope

- 55,000 psi pump

- Material thickness up to 7″ on slats, 30″ with custom fixture

- Cuts any material except tempered glass

- Equipped with Flow ultra pierce vacuum assist for chip free start holes in brittle materials

Safan Darley CNC E-Brake B

- 35 Ton

- 50 Inch DIE/PUNCH Length

- Maximum Bend to Edge distance 48”

- Minimum Bend Radius 1mm

- RADAN RADBEND CNC Software

Paint Booth

- 8’ x 10’ x 10’ Work Area

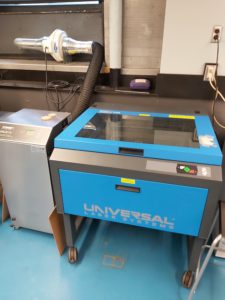

Universal Laser Cutter

- 18” x 24” Bed Size

- 60 Watt Power

Laserstar Laserwelder

- 150 Watt Power

- Nd:Yag laser source