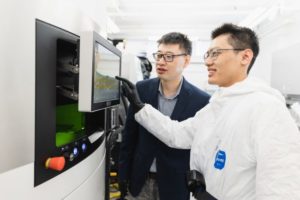

A team of U of T Engineering researchers led by Professors Yu Zou (MSE) and Tobin Filleter (MIE) has received $2.8 million from the Canada Foundation for Innovation’s Innovation Fund (CFI-IF) to develop the Toronto Integrated Platform for Materials under Extreme Conditions (TIME).

This facility will house equipment to test materials in many severe conditions — from temperatures above 1,000 Celsius to a vacuum space empty of matter that replicates outer space — for use across various industries, including space exploration, critical minerals, nuclear energy, zero-emission vehicles and medicine.

“We’re pushing the limit of material performance to design a new generation of materials and this facility will play a crucial role in achieving this goal,” says Zou, who leads U of T’s first metal additive manufacturing lab, and specializes in designing advanced metal alloys and composites for biomedical, automotive and energy applications.

TIME will be a shared space equipped with a wide range of cutting-edge machinery that will enable researchers from diverse fields and faculties to test the performance of materials.

Co-applicants on the CFI-IF proposal include Professors Fae Azhari (CivMin, MIE), Gisele Azimi (ChemE, MSE), Adele Changoor (Surgery, MSE), Thomas Coyle (MSE), Xinyu Liu (MIE), Chandra Singh (MSE) and Ning Yan (ChemE).

“This facility will help us understand how materials behave and degrade in harsh environments,” says Filleter, who is the principal investigator of the Nanomechanics and Materials Lab. His research focuses on nanostructured material and tribology.

“It’s particularly important for industries like space exploration and nuclear energy.”

Developing materials for space applications that can withstand harsh conditions for long periods of time without needing to be serviced is a major challenge. Satellites and space stations need to deploy equipment, such as solar panels, in the vacuum of space, and the materials used in coating these mechanisms and gears need to operate flawlessly to ensure the equipment’s functionality.

These coatings need to survive extreme temperature fluctuations — from launch conditions on Earth and the mechanical agitations during launch, before ultimately being used in space. “Oil-based lubricants don’t work in a space environment,” says Filleter, “so this facility will allow researchers to design and test solid material coatings that have low friction and low wear over a long time.”

“Making the materials work at all stages of use is a real challenge. Service is not an option, so the equipment needs to not only work well but last for a very long time, or else you have a million-dollar piece of space junk that doesn’t work properly,” adds Filleter.

The research conducted in this lab will also have implications in nuclear research, specifically in the construction and operation of small modular reactors (SMRs).

There is a big push from the Canadian government for SMRs as an option to meet their clean energy goals. However, the working environment for SMRs differs significantly from traditional Canada Deuterium Uranium (CANDU) reactors, as they operate in extremely corrosive and high-temperature environments.

With SMRs representing a potential solution for clean energy in the face of climate change, researchers will need to develop and test materials that can endure the radiation, high temperatures and corrosive conditions.

The TIME platform will also support the Canadian Critical Minerals Strategy by developing and testing new tooling materials for the exploration and recycling of critical minerals.

“Currently, there is no such testing platform where we can verify and test various materials in these extreme conditions,” says Zou. “Our platform will provide a new and unique capability to conduct these tests.”

U of T is positioning itself at the centre of materials discovery, development and testing. The Acceleration Consortium is combining material science with advanced computing, artificial intelligence and robotics to rapidly design new materials. Alongside research at the TIME facility focused on testing these materials under real, extreme conditions, the university will be able to work on materials development synergistically.

Researchers at TIME will also train the next generation of researchers in this field, with plans to support approximately 100 students over the next five years, further contributing to advancements in materials science. The TIME platform will address pressing industry challenges and holds the potential to drive innovation, create a knowledge hub for researchers and foster interdisciplinary synergies across the university.

– This story was originally published on the University of Toronto’s Faculty of Applied Science and Engineering News Site on March 13, 2024 by Selah Katona.