March 21, 2017 – Students at U of T Engineering can now choose to learn how to manipulate the materials and methods that will shape future generations of everyday products, from wearable electronics and communications devices to self-driving vehicles and innovative medical diagnostics.

March 21, 2017 – Students at U of T Engineering can now choose to learn how to manipulate the materials and methods that will shape future generations of everyday products, from wearable electronics and communications devices to self-driving vehicles and innovative medical diagnostics.

U of T Engineering’s new optional minor in Advanced Manufacturing will prepare tomorrow’s engineering leaders to design the products of the future, as well as the systems for fabricating their components and delivering them to customers.

Set to launch in fall 2017, the multidisciplinary program provides a strong foundation for aspiring product managers, researchers or entrepreneurs. It joins seven other minors that U of T Engineering students can pursue as they tailor their degree toward their academic interests, including Bioengineering, Sustainable Energy and Engineering Business.

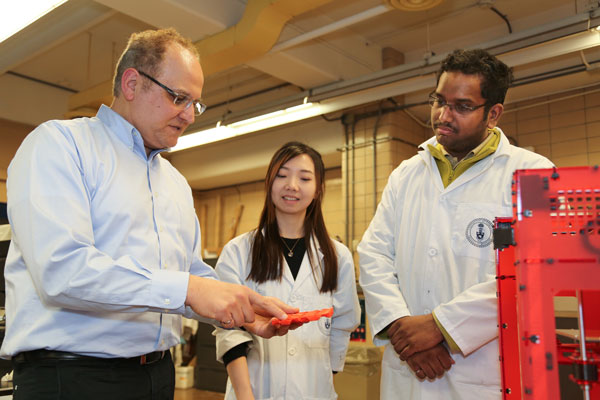

“We have a major manufacturing hub here in southern Ontario, and manufacturing is one of the key drivers of the global economy,” says Hani Naguib (MIE, MSE) director of the Toronto Institute for Advanced Manufacturing, which is coordinating the new program.

Naguib points to Canadian companies such as Bombardier in the aerospace industry and Celestica in electronics as examples of thriving enterprises with a need for innovative manufacturing expertise. But he also has an eye on early-stage industries that have the potential for major growth in the coming years.

“If we really want to compete worldwide, it has to be with high-end products: biomedical devices, wearable technologies, electric vehicles,” says Naguib.

The new minor draws on the Faculty’s strengths in three key areas:

- Advanced materials — Nanoengineering could lead to materials that are ultra-strong yet lightweight, or that replace fossil-fuel-derived plastics with plant-derived alternatives. This area also includes ‘smart materials’ that respond to changes in their environment, critical for making sensors in wearable technology or self-driving vehicles.

- Advanced processing — Additive manufacturing (also known as 3D printing) enables each component or product to be customized at very low cost. New forms of laser cutting and coating technologies could shrink the size and cost of electronic devices while increasing their power.

- Advanced logistics — Big data provides an opportunity to make smarter decisions about scheduling, supply chains, transportation and delivery. This has the potential to reduce waste, lower costs and enhance the efficiency of manufacturing operations.

In addition to these technical aspects, the new minor also includes courses that emphasize management competencies, delivered in collaboration with the Institute for Leadership Education in Engineering. “There is no manufacturing without leadership,” says Naguib.

Naguib expects that graduates of the new program will take a variety of paths: some will hold senior positions in manufacturing companies, while others will create new companies to build products that haven’t been invented yet.

“It’s amazing to see how far our students go with an idea,” says Naguib. “We have our own startup incubators such as The Entrepreneurship Hatchery and Start@UTIAS, and we’re close to other U of T entrepreneurship accelerators in the Banting and Best Centre, as well as MaRS. What we’re providing is a foundation that covers the entire process, from engineering to management to logistics.”

Applications for the Advanced Manufacturing Minor are now open to first-year students in all disciplines, and there is no limit on the number of spaces. Courses will begin in September 2017.