MIE's machine shop houses state-of-the-art equipment and provides technical services for U of T Engineering students and faculty.

All U of T Engineering students and researchers have access to use the machine shop facilities for projects related to U of T academic activities or student clubs. Users must pass a basic machining course and meet other requirements (jump to Access Requirements).

The Machine Shop technicians also provide professional services to support faculty and student research at MIE and the wider U of T community including design consultation, precision machining, fitting and assembly of prototypes and custom-designed parts. Machine shop staff do not take on contract work for corporations, private individuals, alumni or small businesses.

Location & Hours of Operation

The Machine Shop is located at MC 78, on the lower level of the Mechanical Engineering building, Room 78, 5 King's College Road.

Machine Shop hours may vary during exam periods and special occasions. Check MC78 entrance-way for updated hours. Shop may be closed for lunch (12-12:45 pm) and dinner breaks (5-5:45 pm).

During academic year

- Monday to Friday:

8 am - 9 pm - Saturday:

9 am - 4:30 pm - Sunday:

Closed

May - June

- Monday to Friday:

8 am - 4 pm - Weekends:

Closed

July - August

- Monday to Friday:

8 am - 3:30 pm - Weekends:

Closed

Student Machine Shop

Use of Student Machine Shop

- Only those who have completed the access/training requirements will be permitted into the student shop.

- Users will need to book a time slot on a specific machine, using Microsoft Bookings found at the following link. Log in with your UTORid (works best on Chrome browser).

Booking Link - Users may book one time slot on either the lathe, mill, FARO arm/Laser cutter, paint booth or training. Book a lathe for round parts or a mill for flat parts you are working on, if you're not sure which to use just select either the lathe or mill, even if you are only doing bench work.

- You must show up for your time slot before booking an additional time slot. If you book more than one time slot before showing up to your first booking, the system administrator will delete all other scheduled bookings.

- Only the user who booked the time slot will be permitted to enter the student shop. Trading of time slots will not be permitted.

- Users must have their part drawing ready before showing up to their booked time.

- For additional information contact the student shop machinist Jeethandra Anayat or Shawn Miehe:

Contact Information

-

- Tel: 416-946-3358

- Email: jeeth@mie.utoronto.ca or shawn@mie.utoronto.ca

Applicants requesting access to the Student Machine Shop must:

- be a researcher, undergraduate (including those on PEY) or graduate student of U of T's Faculty of Applied Science & Engineering.

- pass a 2-day hands-on introductory Basic Machining course offered by George Brown College to U of T students, which is offered approximately 15 times per year. There is a non-refundable fee of $175 for the course. See upcoming courses on the Machining Courses Calendar.

- Complete the Online MIE health and safety course at www.mie.utoronto.ca/safetytest. There is no fee. Researchers who do not have a UTORID please email mieHs@utoronto.ca. Please note, you cannon substitute any other safety course for the MIE safety course. You will need to provide proof of completion.

- review the Student Shop Safety Manual, training documents for proper use of equipment and shop rules (see documents and rules below)

After all above requirements have been met, applicants must:

- sign up through the Booking Link for the MC78 Site Specific Safety Training and Orientation about how to safely operate the Student Shop's machines and shop rules. The orientation is followed by a short test.

If all above requirements have been met, the applicant goes to the Student Machine Shop to complete their registration. If approved, access to the Student Machine Shop will be granted for the remainder of the academic year until August 31.

To continue to have access to the Student Machine Shop each academic year, students must complete a free annual online refresher safety course. To register for the refresher course follow this link: www.mie.utoronto.ca/safetytest. Note that students do not need to complete the Basic Machining course each year - students only need to pass the course once.

Equipment and services

- Assistance and consultation

- Bridgeport Milling Machines

- Drill Presses

- Hand tools

- Hardinge Lathes

- FARO arm

- Sheet metal sheer, hole punches and bending machines

- Milling cutter and Lathe tool bit kits

- Vertical Bandsaw and Cutoff Saws

- Workbenches and Vices

- Laser Cutter

Rates

- U of T Engineering undergraduate students: Covered by departmental Chair's Office

- MIE graduate students: Covered by MIE Chair's Office

- Non-MIE engineering graduate students and researchers: $25/hour, covered by your professor or supervisor. The Student Shop Charge Authorization Form must be signed and submitted before an access pass will be issued.

Student Shop Training Documents & Rules

Professional services

Contact

Tel: 416-978-6008

Email: Ryan Mendell, Machine Shop Manager, ryan@mie.utoronto.ca

Services offered

- 3D Printing

- 3D Scanning

- Brazing

- CMM Arm

- CNC Brake Press

- CNC Lathe

- CNC Milling

- CNC Programming

- Electro-Discharge Machining (EDM)

- Fitting/Assembly

- Laser Cutting (Non-metals)

- Manual Machining

- Optical Comparator

- Sandblasting

- Surface Grinding

- Waterjet Cutting

- Welding/Laser welding

Outsourced services:

- Anodizing

- Cylindrical Grinding

- Heat Treatment

- Laser Cutting (Metals)

- Rolling/Forming

- Welding

Rates for professional services

- MIE faculty and students: $67.50/hour

- Other U of T departments: $77.50/hour

- 3D printing: $5/hour of machine time + material costs

How to Request Professional Services

Step 1

Submit your request and accompanying files to Machine Shop Manager Ryan Mendell (ryan@mie.utoronto.ca).

For Machined Components you must submit:

- engineering 3 view drawings (computer generated or by hand) OR CAD files (.sldprt, .slddrw, .Iges, .dwg, .dxf, .step) and

- all necessary supplementary component drawings.

For 3D printing you must submit:

- .stl files

Do not send .stl files for machined components drawings.

If you are unable to produce proper drawings, contact Ryan to arrange a consultation meeting

Step 2

A quotation will be provided upon receipt of a successfully submitted request. For a quotation to be provided you must include proper drawings as described in Step 1.

Step 3

If you would like to proceed with the work based on the quotation, complete the Professional Services payment form and email to ryan@mie.utoronto.ca

Professional equipment

CTX 310 Glidemeister CNC Lathe

- 14.5″ swing by 17.5″ between centres

- 6,000 rpm spindle

- 12 position tool turret

Kitamura Mycenter 3020G

- 30″ x-axis travel by 20″ y-axis travel by 20″ z-axis travel

- 20,000 rpm spindle

- 30 tool Automatic Tool Changer

- 1 micron repeatability

HAAS VF-2 SS Vertical Machining Centre

- 30″ x axis travel

- 16″ y axis travel

- 20″ z axis travel

- 12,000rpm

- 24+1 tool changer

Sodick AD325L CNC Wire EDM

- 12.5″ x-axis travel by 9.5″ y-axis travel by 8.5″ z-axis travel

- wire size of 0.006″ to 0.012″

- 15 degree per side taper cutting

- 0.1um resolution

Agie Charmilles Drill 11 NC EDM Hole Driller

- 12″ x-axis travel by 8″ y-axis travel by 12″ z-axis travel

- drill sizes from 0.006″(0.15mm) to 0.125″(3mm)

- can drill up to depth of 200 x (electrode diameter)

Sodick AD25L Sinker EDM

- Work Tank Size: 23.62" x 17.87" x 10.24"

- X-Axis Travel: 11.81"

- Y-Axis Travel: 7.87"

- Z-Axis Travel: 5.91"

- Max Workpiece Weight: 220 lbs

- Max Electrode Weight: 44. lbs

Fortus 450MC 3D Printer

Haas TM-1 CNC Tool Room Mill

- 30″ x axis travel

- 12″ y axis travel

- 16″ z axis travel

- 4,000 rpm

Roland 3D scanner

- 10″ dia x 16″ H – Work Envelope

- 0.004″ scan resolution

- rotational and planer scanning

Flow Mach 2 CNC Waterjet

- 52″ x 52″ Work Envelope

- 55,000 psi pump

- Material thickness up to 7″ on slats, 30″ with custom fixture

- Cuts any material except tempered glass

- Equipped with Flow ultra pierce vacuum assist for chip free start holes in brittle materials

Safan Darley CNC E-Brake B

- 35 Ton

- 50 Inch DIE/PUNCH Length

- Maximum Bend to Edge distance 48”

- Minimum Bend Radius 1mm

- RADAN RADBEND CNC Software

Paint Booth

- 8’ x 10’ x 10’ Work Area

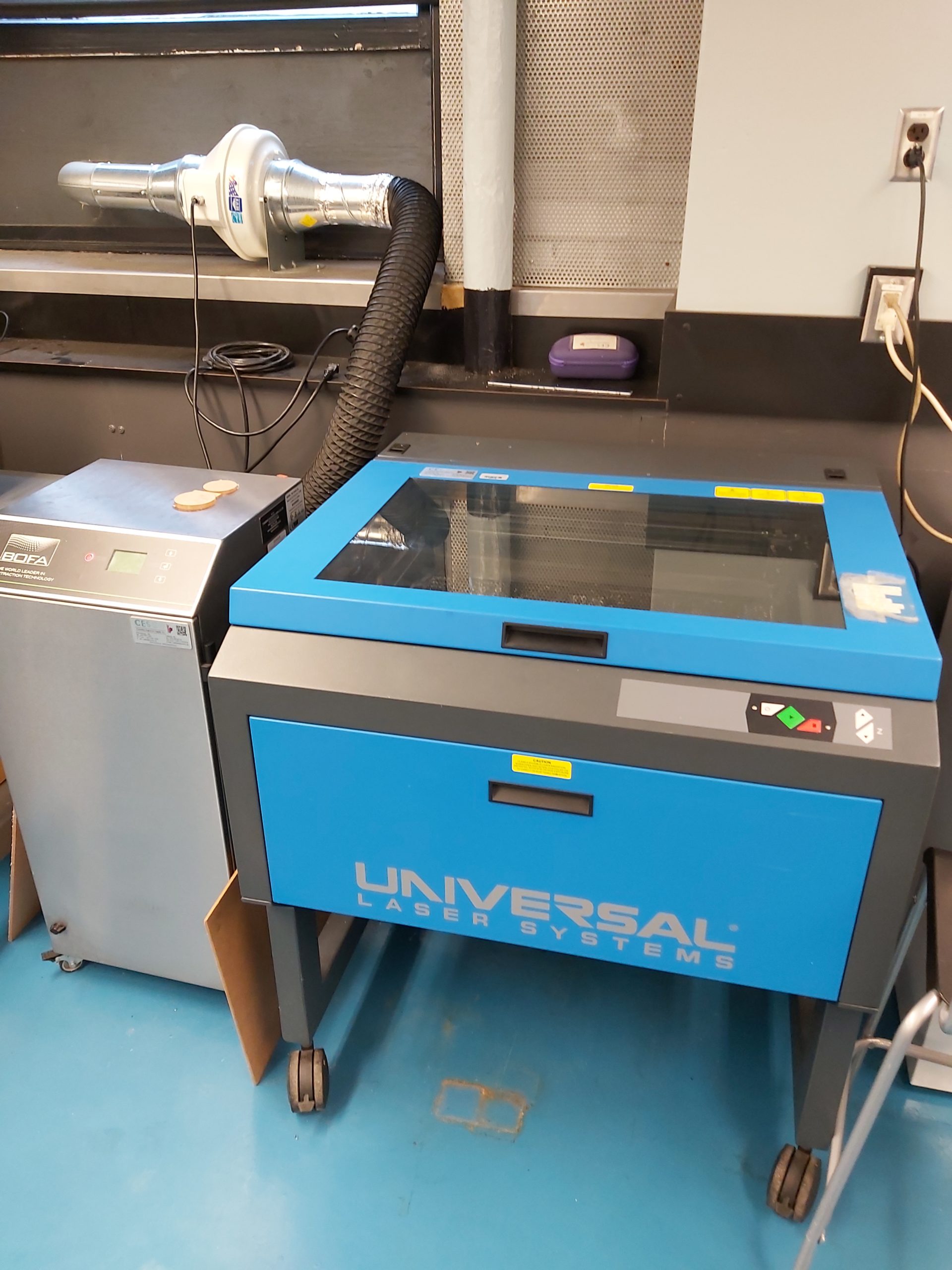

Universal Laser Cutter

- 18” x 24” Bed Size

- 60 Watt Power

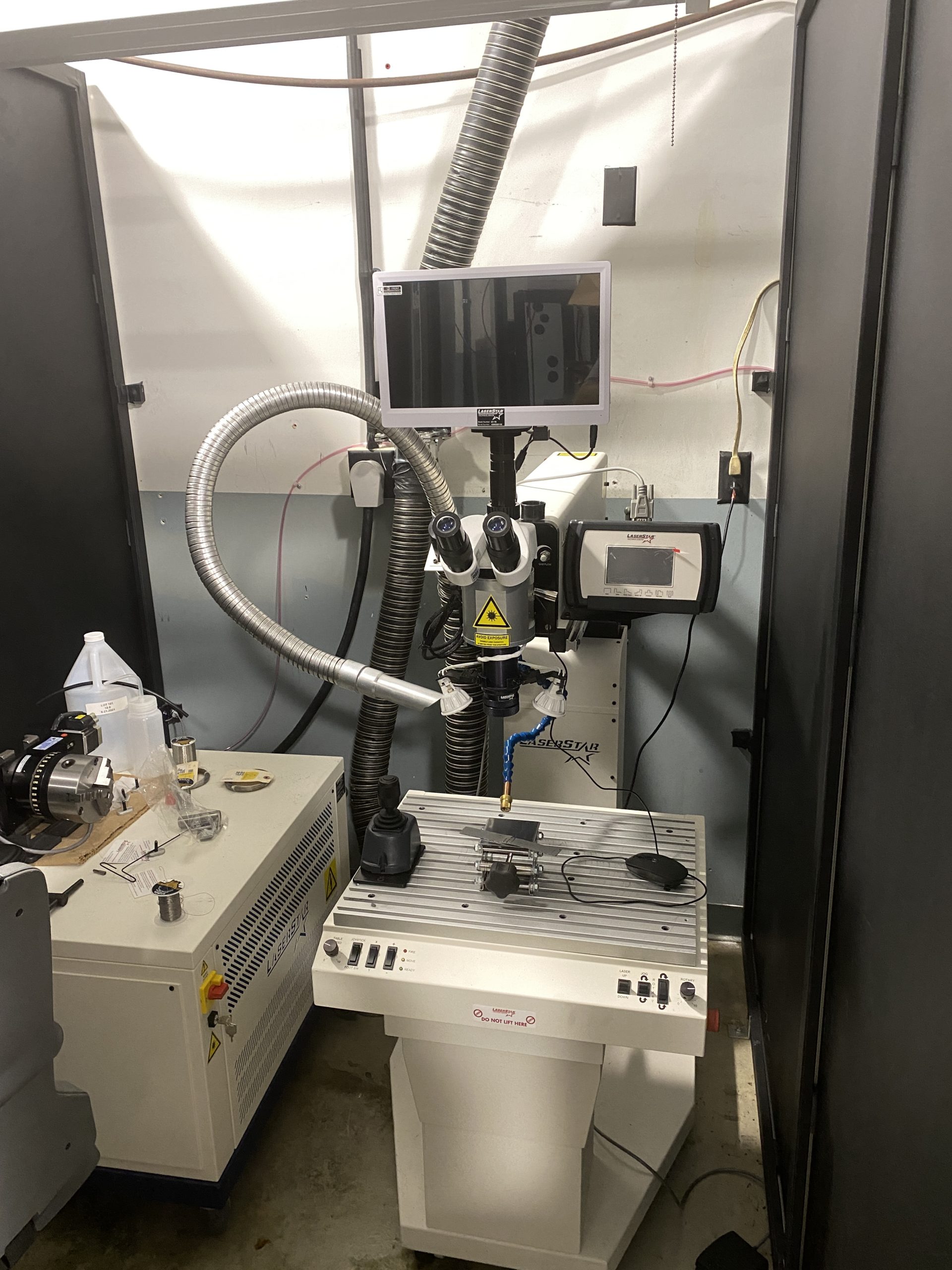

Laserstar Laserwelder

- 150 Watt Power

- Nd:Yag laser source